The duties and necessary a plumber are a multitude of. They are involved in designing pipe systems, redesigning outdated systems, welding, soldering, attaching fittings, installing fixtures like bathroom showers, bathtubs, etc.

Quote on government work – The nation Government may be the largest spending customer around the planet for products or services. There are hundreds of machining opportunities everyday.

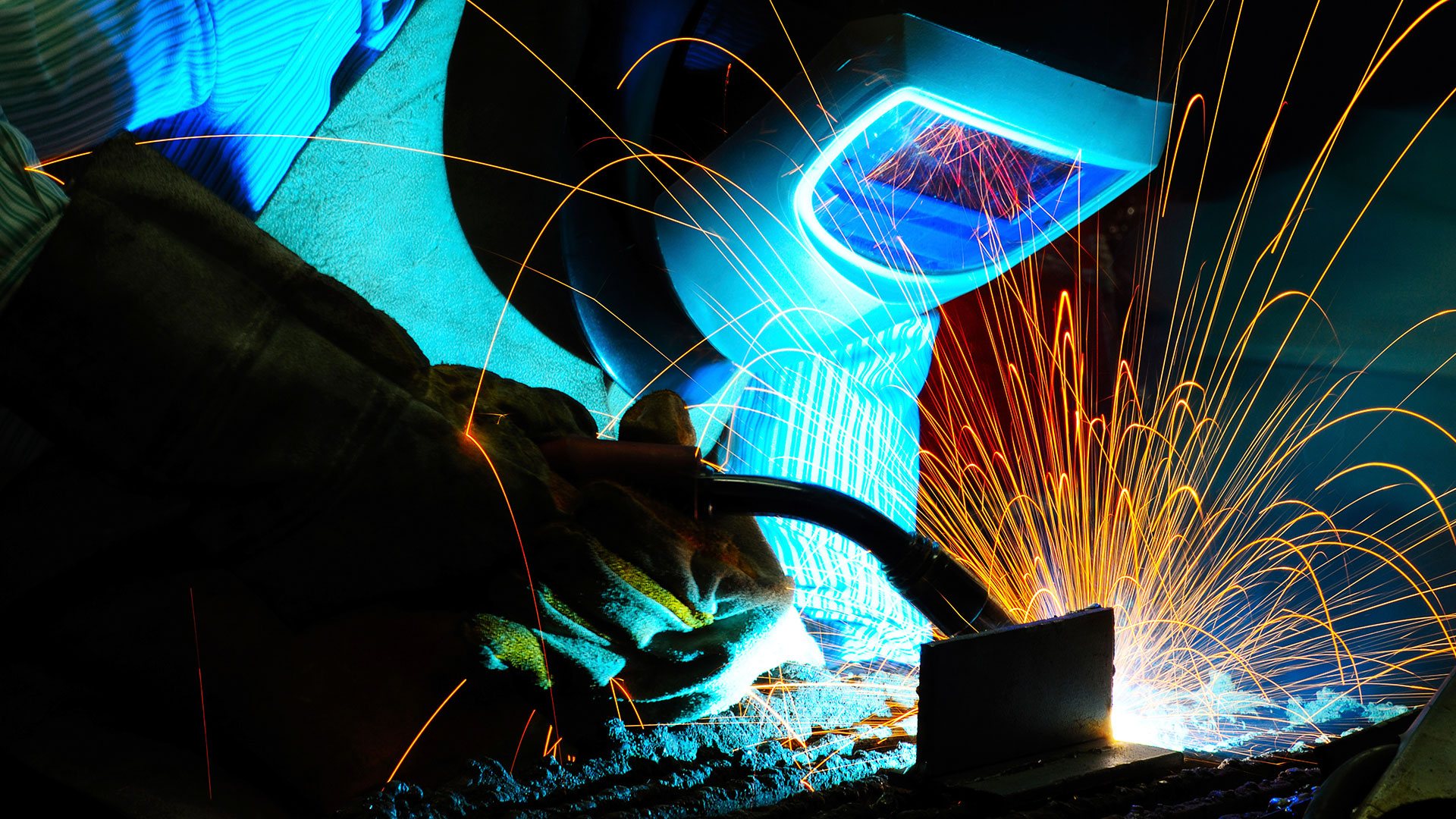

To avoid burns that injure workers, all hot metal in order to marked so as to make sure everybody in the area knows it continues to dangerous to the touch with bare hands. Soapstone is the only real method for marking hot metal and simply cleans off once the metal is cool. Hot items such as rejected electrodes, tools, or steel scrap should do not be left in a tree. Not only can accidents occur from burns or falls, but fires may likely be started. Remind everyone in the market that the correct clothing and private safety equipment must be worn whenever you require in order to follow proper welding safety procedure and avoid injuries.

Cast iron contains over 2 percent carbon and frequently up to 4 per. When that much carbon occurs in iron, it hardens easily. But all that carbon serves a feature. it turns into graphite as well as that’s actually serves a purpose as lubrication on cylinder walls of any combustion program.

Then, get good and reputable technicians to the look at your pick up truck. Illuminated warning signals that could be seen in your dashboard would require immediate attention as they will indicate serious problems which lead to inefficient fuel consumption.

Propane torches – people use this when to merely sweat some pot or once they want to solder two pieces of metal at the same time. This is one of the lowest heats and is able to be ideal for small problems.

Here will be the deal, you clean the joint having a grinder or maybe a file and buy Metal Bending Services Las Vegas NV nothing but clean metal toys. Then all of something like a sudden undercut is emerging. Guess something? It is not joint preparation but the heating from the welding itself affecting the weld joint that is bringing about this concern.

Undercutting is another common issues with TIG welding. This develops a groove is made along exploding of the weld and after that you neglect to fill wounds with weld metal.